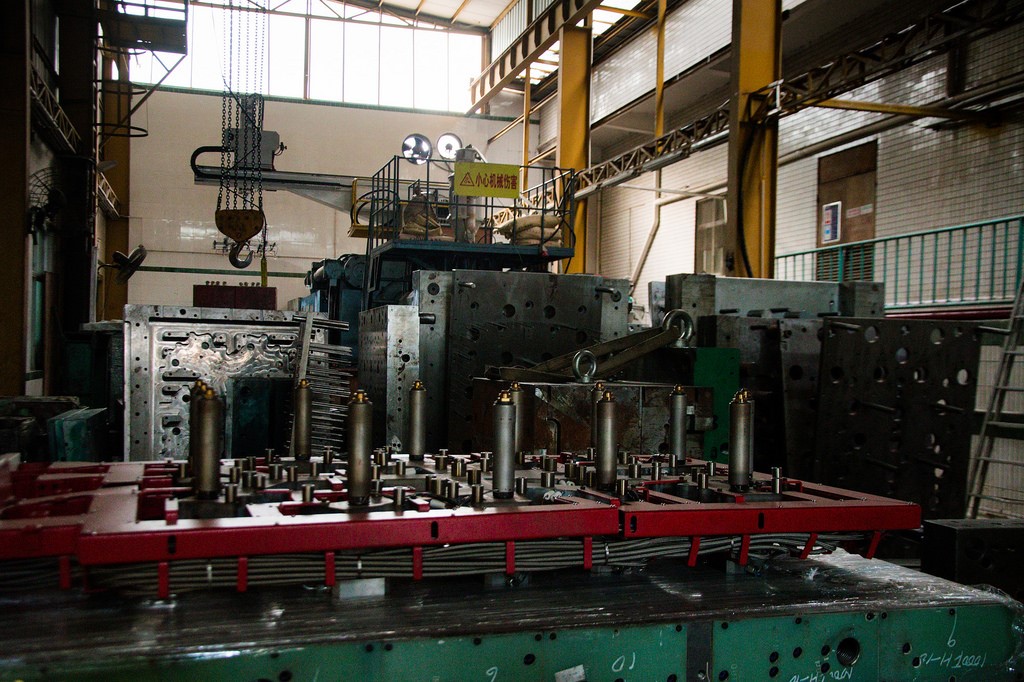

Eight advantages of plastic injection moulding

Injection moulding has become a very popular way of producing large volumes of parts efficiently and at a low cost. It is used in multiple different industries and offers lots of benefits, eight of which are explained below.

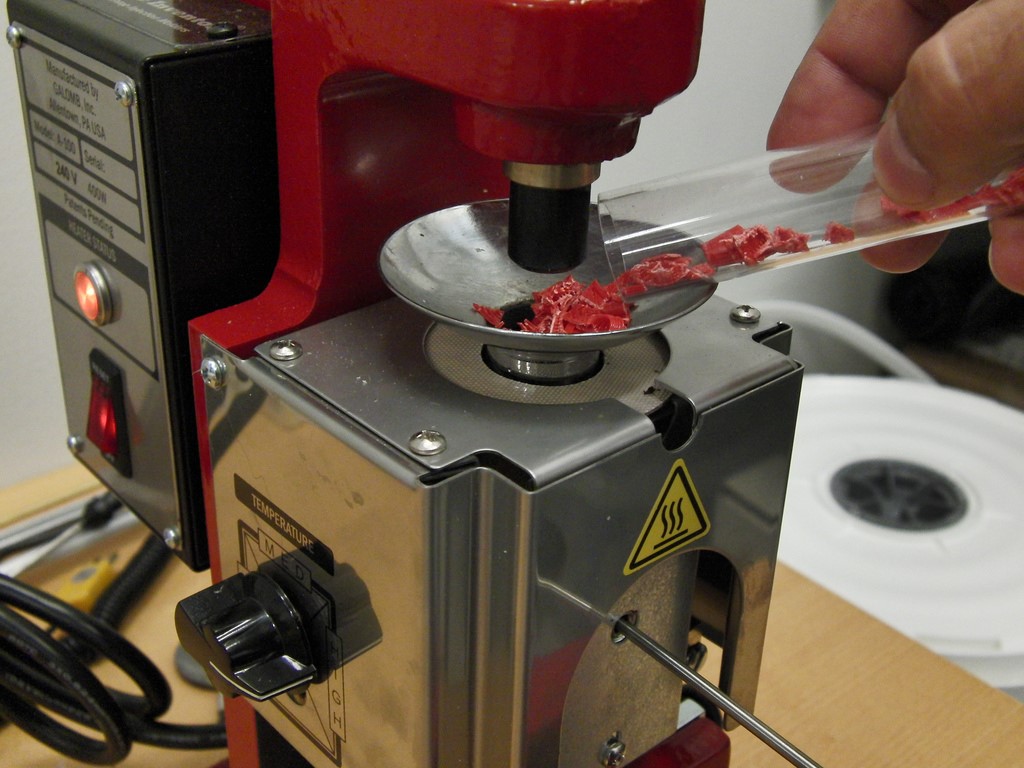

1. Plastics with multiple purposes

With injection moulding, there is no need to choose just one type of plastic. Multiple plastics can be used to create a premium product that is purpose-built for its function.

2. A quick and efficient option

When compared with other options, injection moulding is quick and efficient. Once the moulds have been created, the presses are pre-programmed. The output is speeded up and only one mould is needed to create hundreds or thousands of the same product.

3. Easy replication and consistency

With injection mouldings from companies such as http://www.meadex.co.uk, the ability to replicate products on a large scale is a reality. The results are always consistent, even for complex shapes, so a high-quality product can always be produced.

4. A strong end result

Plastic moulded parts enable a filler to be added. This can reinforce them and make them stronger, which is not always possible with other moulded products.

5. An automated process

Plastic injection moulding is automated, so there is no reliance on staff or a need for a great deal of manpower. Machines do all the real work – all that is needed is someone to programme the machine, set it up, and monitor the results. This means it is more cost effective, as there are no huge fees attached for labour.

6. Eliminating post process requirements

This type of moulding results in a high-quality finish and there is little to no post-production work required to make them look good. All parts look finished as soon as they have been moulded, which reduces time and costs greatly when compared with other methods.

7. Adding details

Due to the high pressure used in this process, the plastic can be moulded into the most intricate designs with a great amount of detail. This also allows for the personalisation of a product or for small details to be included that may otherwise have had to be added by hand.

8. An environmentally-friendly option

This type of production is environmentally friendly, as all waste is recycled and reused.