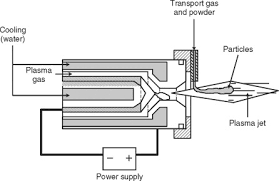

Plasma Polymer Systems and their uses

Layered plasma polymer composite liquid separation systems are disclosed, that contain both permeable and selective layers for a maximum of up to 2 n layers, where n is the total number of different selective layers used in the separation process. These systems can be used to separate various solvents, grease, lubricants and other liquids. Polymer blends having high tensile strength and durability can also be used for the separation of solvents. They are formed by the combination of thermoform and plastic polymers with the help of fusion reactions between plasticizers. They are capable of retaining their solid form for longer periods. This complicated process is well understood by Poeton.

These polymers are generally chosen for their flexibility, pliability, as well as the ability to maintain their solid structure over a wide range of temperatures. In addition to this, they have the potential to exhibit both high tensile strength and high compressive strength, depending on the type of filler used. They are also used in various industries for various purposes such as lubrication, sealing, coating etc.

The plasmas produced by plasma polymer systems offer several advantages over the other common processes of separation. These include: flexibility, the ability to maintain their solid structure at all times, the ability to form thicker and thinner films as required, the ability to exhibit different phases of plastics with the help of different temperatures and the ability to be cycled without causing permanent damage. This allows the plasma polymer system to be used in a variety of applications, thus ensuring its widespread application in the manufacturing industries.